產品介紹

陶瓷散熱基板 薄膜製程

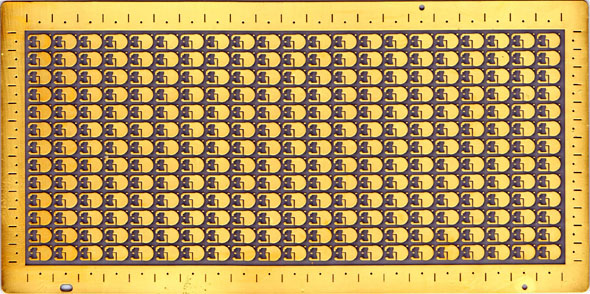

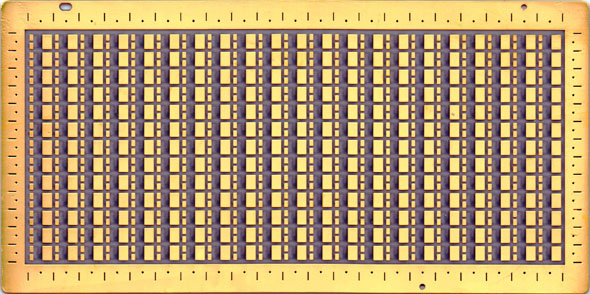

利用半導體薄膜製程中的濺鍍、電鍍/化學鍍沉積、曝光顯影等技術,在陶瓷板上做金屬化加工,刻畫電路圖形,開發出薄膜陶瓷基板製程(DPC,Direct Plate Copper,直接鍍銅基板)。

陶瓷散熱基板結合陶瓷優異之散熱能力及金屬之導體特性,具有熱傳導率佳、厚度薄、尺寸小等特點。結合薄膜製程更使其具有產品線路附著性佳、表面平整度高、及對位精準等優點,產品應用極為廣泛。

主要應用:

- 1. 高功率LED封裝基板

- 2. 太陽能電池

- 3. 車用電子

- 4. 微波無線通訊

- 5. 半導體設備

Substrate Physical Properties:

| Characteristic Value | AlN | Al2O3 (96%) |

|---|---|---|

| Color | Gray | White |

| Density | 3.3 g/cm3 | 3.7 g/cm3 |

| Thermal Conductivity | ≧170 W/mk | ~22 W/mk |

| Coefficient of Thermal Expansion | 4.6 x 10-6/℃ (R.T.~400℃) | 7.3 x 10-6/℃ (25~800℃) |

| Dielectric Strength | 15 KV/mm> | 14 KV/mm (AC 60Hz) |

| Volume Resistivity | ≧1013Ω‧cm | ≧1014Ω‧cm (25℃) |

| Dielectric Constant | 9.0 1MHz | 9.4 1MHz |

| Bending Strength | ≧330 MPa | ≧320 MPa |

Specification

| Characteristic | ALN | Al2O3 (96%) | |

|---|---|---|---|

| Substrate Part | Dimensions | Up to 4.5” x 4.5” | Up to 5” x 5” |

| Dimensional Tolerance | ±1% NLT ±0.1mm | ±0.60%, NLT : ±0.08mm | |

| Thickness | 0.38 / 0.5 / 0.635 mm | 0.38 / 0.5 / 0.635 / 1.0 mm | |

| Thickness Tolerance | ±10% > | ±10.0%, NLT : ±0.05mm | |

| Metalized Part | Conductive Layer | Cu-Ni-Au / Cu-Ni-Ag / Customized Up to 100μm in Thickness |

|

| Via Hole | φ75μm min | ||

| Pattern Construction | Single Face / Double Face with Via Holes / Customized | ||

電話:+886 2 8792-1266

傳真:+886 2 8792-1266

地址:106台北市大安區基隆路2段136號9樓

電子郵件:soarservice@soar-technology.com

群尚科技有限公司 © 2019 Soar Technology Co., Ltd. All Rights Reserved.